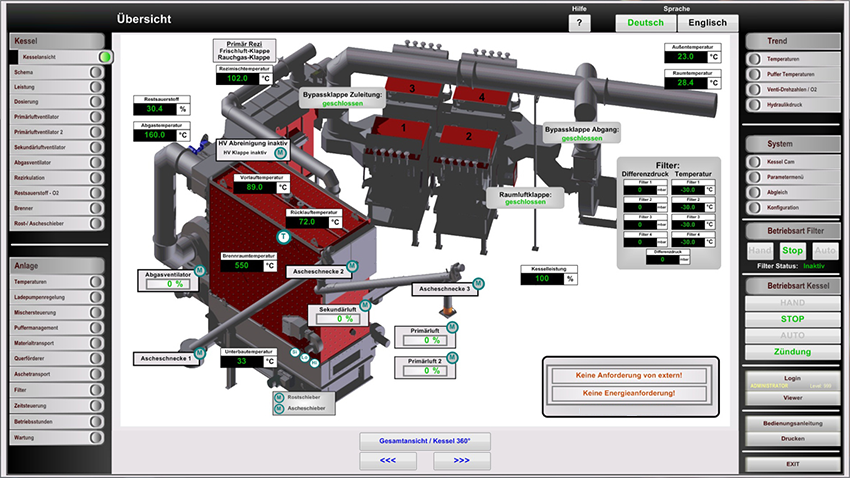

Background

| The BINDER ceramic filter system is a new in-house development and is based on the principle of a filtering separator. The main advantage of a ceramic filter over common bag filters is based on the ceramic filtration medium not being flammable and withstanding higher temperatures (up to 400 °C) without taking any damage. The BINDER Ceramic filter is of modular design and can be adapted individually to the boiler and the fuel used. |

|

Mode of Operation

| The cyclone cleaned exhaust gas enters the ceramic filter through an even flow profile. The flue gas is drawn through each individual filter element. During this process the dust particles are deposited at the filter element’s surface and the cleaned exhaust gas is transported to the flue via the exhaust gas fan. The entire filter housing is built from sheet steel and fully insulated. Auxiliary heating can be added as an option to improve partial load operation.as is transported via a fan to the chimney. |

|

Advantages

|

|

Operation of Compressed Air Cleaning and Dust Removal System

|

The cleaning of each individual filter element works with compressed air by the principle of counter-acting flows. To remove the ash from the ash-hopper of the filter it is possible to install an optional dust removal system which draws the dust regularly in a central ash-container. |

|

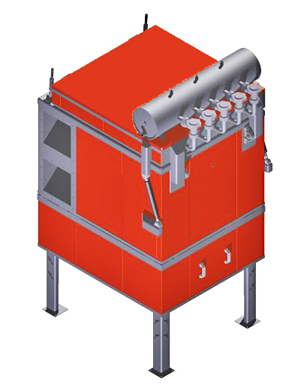

3D visualization of a 840 kW unit with 4 Filter modules