Extraction Systems

BINDER offers different types of extraction systems depending on type of fuel used or on-site requirements. The main purpose of extract systems is conveying fuel from a storage area to a subsequent fuel transport device.

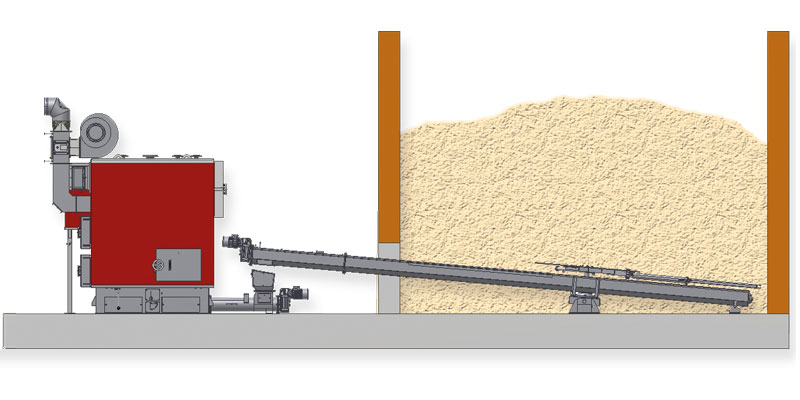

PS – Pellet Extract Auger

Auger with adjustable pressure relief cover for transport of pellets out of a rectangular room with or without slanted floor. Depending on the fuel store size with or without universal joint.

| max. Pellets size | D06 (HP1) with universal joint or D10 (HP1) without universal joint |

| Filling Height | no limitation |

| Typical application | With pellets boilers up to 1,000 kW nominal capacity |

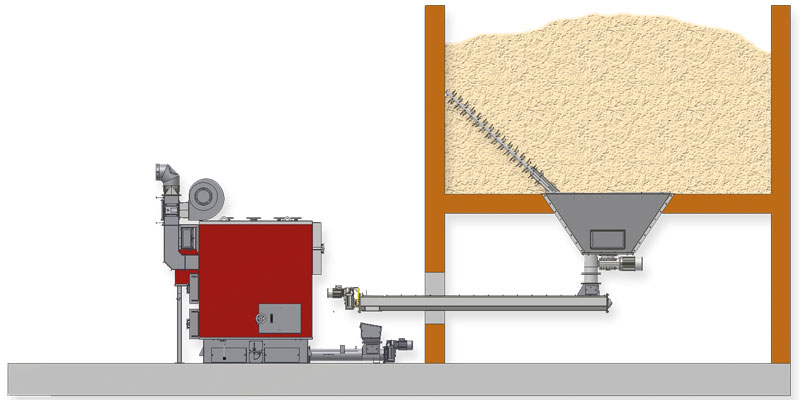

KA – Sweep Arm Agitator

The sweep-arm agitator is a load depending helical cutter. The substantial sweep-arm is independently powered from the auger and operates depending on the amount of fuel inside the fuel store, with variable diameters.

| max. Chip Size | P63 (G100) |

| Filling Height | up to 6.5m depending on design, diameter and fuel bulk density |

| Typical application | With wood chips boilers up to a nominal capacity of 3,000 kW |

SS – Tapered Sweep Auger

Free wheeling spiked auger for fuel extraction out of silos accessible from below.

| max. Chip Size | P45 (G50) |

| Filling height | Up to 20m depending on fuel bulk density |

| Typical application | Extraction of fuel out of round silos |

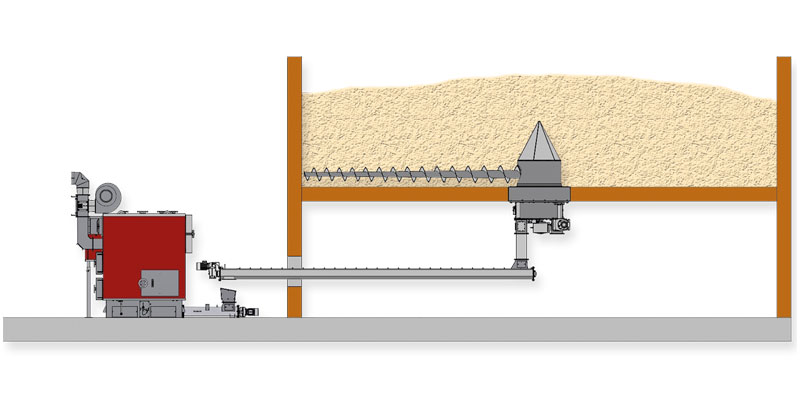

WS – Horizontal Sweep Auger

Guided auger for fuel extraction with silos. The auger is forced by an clamp fitting system through the silo

| max. Chip Size | P63 (G100) |

| Filling height | Depending on used fuel |

| Typical application | With silos of big diameters (> 7m) |

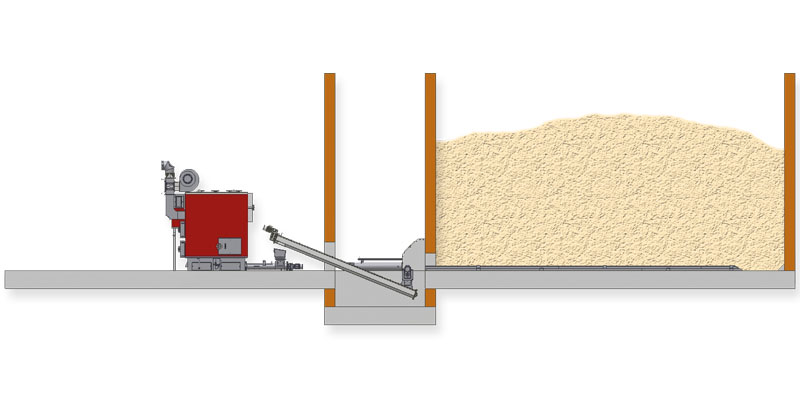

SBA – Walking Floor

Extremely robust, welded steel grid with a hydraulic ram. The walking floor is pushed by the hydraulic ram into the fuel along the fuel store floor and pulls the fuel towards the subsequent transport system at the front end of the walking floor.

| max. Chip Size | P100 and bigger (> G150) |

| Filling height | Depends on design of walking floor and the fuel store size. |

| Typical application | With boilers from 500 kW nominal capacity upwards. |