To make corn, pumpkin seeds and other grain storable it requires drying. As drying is very energy consuming, oil and gas consumption is quite substantial as well. Biomass forms an economical and ecological alternative here as well.

Advantages

|

|

Typical Applications

Indirect Drying

The heat exchanger is use for drying corn, pumpkin seeds, grain, wood chip or logs. To make corn storable, the water content needs to be lowered from approx. 30% to approx. 14%. For this process a significant amount of oil or gas would be required but with a BINDER Air Heat Exchanger cost effective biomass can be used instead.

Object Heating

Another typical application for an Air Heat Exchanger would be heating of halls, tents, green houses or paint shops. The heated fresh air is blow into a distribution duct system and evenly dispersed via louvers. To conserve energy, the heated air is then mixed with fresh air under controlled conditions.

Details

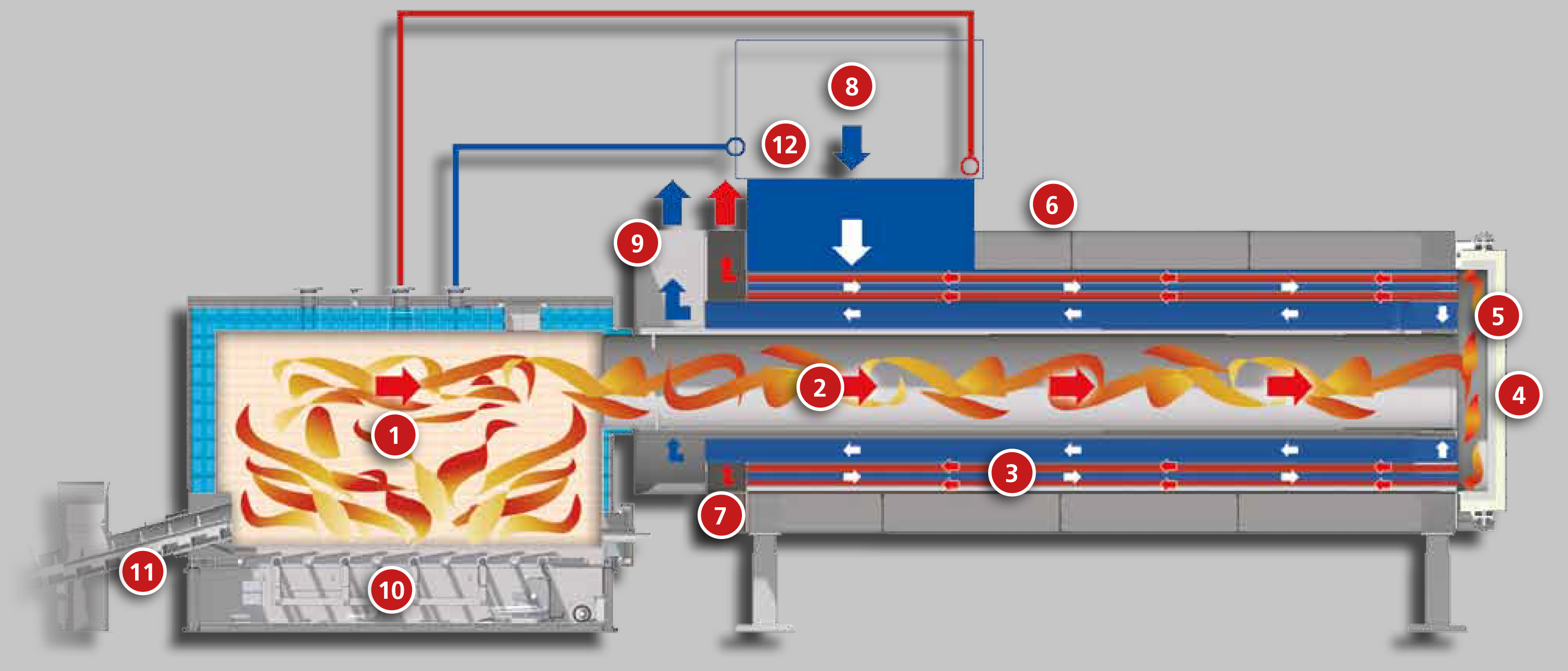

The hot combustion gas is routed into the subsequent exhaust-gas -to-air heat exchanger via a flame tube. Initially the exhaust gas passes through the flame tube into the turning chamber. Here the exhaust gas is redirected into the tube heat exchanger and finally into the exhaust gas duct. During this process the heat transfer from combustion gas into fresh air takes place. The waste heat resulting from water cooling the combustion chamber is reused in a water-to-air heat exchanger to pre-heat the fresh air as well.

The pressure of the fresh air is maintained higher than the combustion gas pressure to avoid contamination of the fresh air.

Cross Sectional Diagram

|

|||||||

| Water cooled combustion chamber | Flame tube | Heat exchanger tubes | Cleaning door | ||||

| Turning chamber | Air-to-air heat exchanger | Exhaust gas outlet | Fresh air inlet | ||||

| Fresh air outlet | Combustion unit | Boiler fuel feed system | Fresh air pre-heating | ||||

Potential Savings

When harvesting corn the corn cops are separated from the corn. The corn is then processed whereas the corn cops and straw are not used and often remain in the fields. With a BINDER boiler in combination with a BINDER Air Heat Exchanger this waste material becomes valuable fuel . In the majority of cases the energy required for drying the corn is available through the otherwise wasted corn cops. Therefore no additional drying costs arise when exclusively using the available corn cops. The corn field is producing fuel as a side effect.

If you have any questions regarding the Air Heat Exchanger and its potential savings, please do not hesitate to contact us