Technology always develops from the primitive to the complicated and than to the simple

(Antoine Saint-Exupéry)

BINDER offers a wide range of different heating solutions, starting from warm to hot water, to air-to-air heat exchangers, to saturated steam boilers, to combustion chamber only solutions. The biggest advantage of BINDER is total flexibility. True to the motto “Nothing is impossible” our engineers will seek to provide an optimum solution for your requirements.

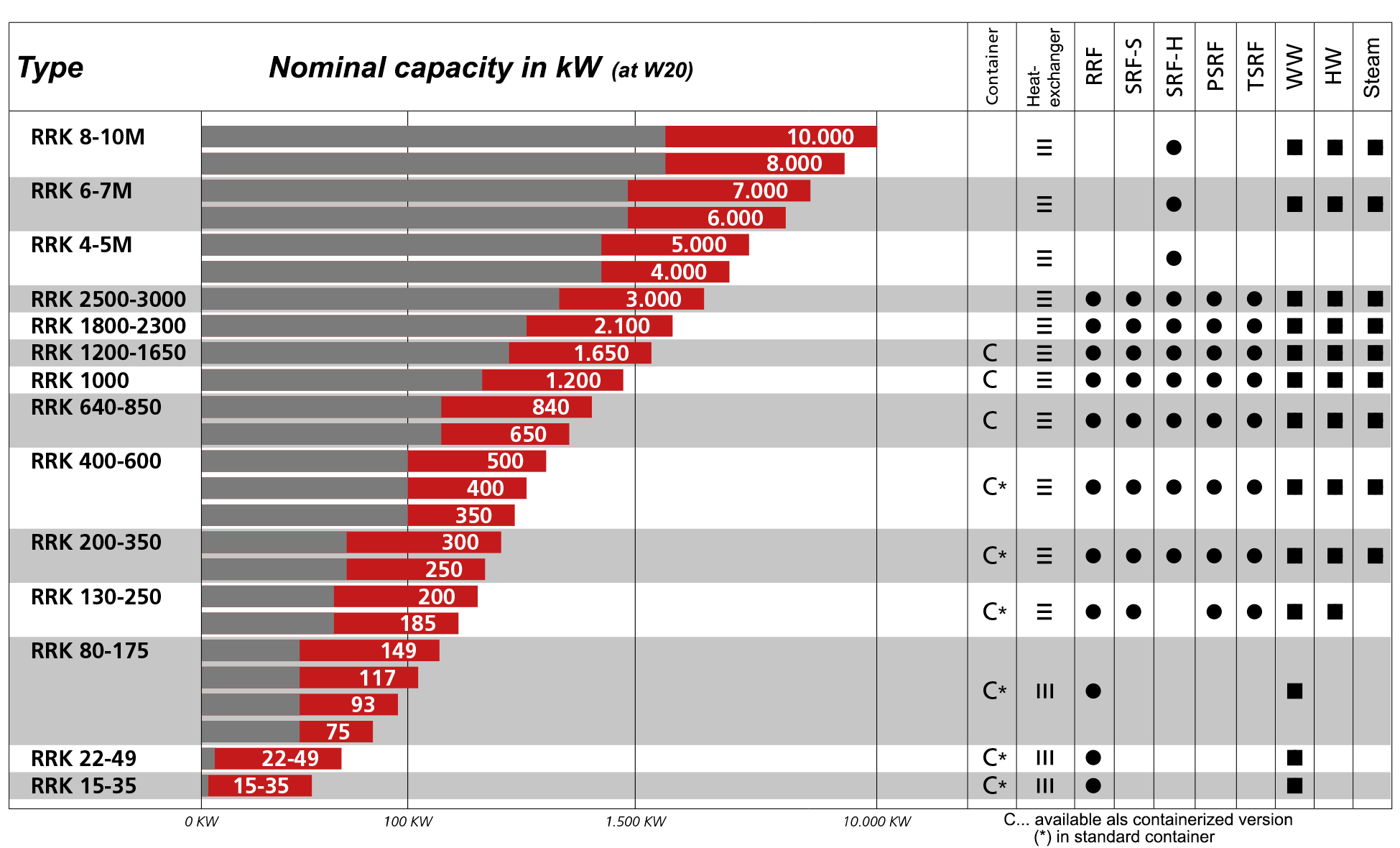

Below you will find an overview for the available standard boiler sizes provided by BINDER. If you have any questions regarding special solutions please contact our sales department.

Boiler Range

Below an overview of available boiler capacities and model ranges. Also included are the available combustion units.

System overview

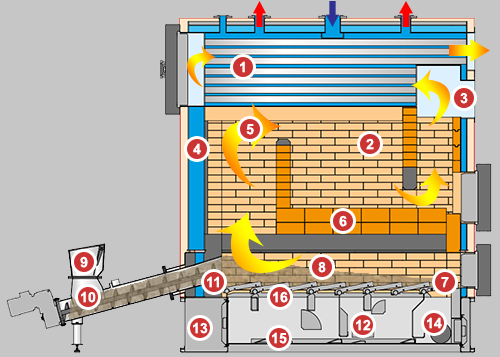

A BINDER boiler type RRK 400-600 in combination with an moving grate combustion unit SRF:

|

Heat Exchanger best-practise chamfered and root welded, individually replaceable if required |

Refractory with standard firebricks instead of manufacturer specific moulded bricks: simple and cheap to replace |

|

Heat Exchanger Cleaning

|

Water-cooled Boiler Jacket

|

||

| Secondary Air Supply λ-controlled, with optimized arrangement of nozzles for superior turbulent flow |

Radiation Arch optimized air flow, completely lined with refractory brickwork |

||

| Grate Screen prevents ash-auger damage by falling debris |

Combustion Chamber

|

||

Anti-Burnback Provisions

|

Feeding System

|

||

Moving Grate Boiler >150 kW

|

Primary Air Supply λ-controlled, with load-dependent distribution to combustion and burnout zone |

||

Industrial Quality

|

Ash Auger for removal of ash into the central receptacle optional with ash lock or hydraulic de-ash ram |

||

| Ash Scraper for de-ashing of the entire boiler base |

Grate Element made of high temperature cast chromium alloy, separately replaceable |

||