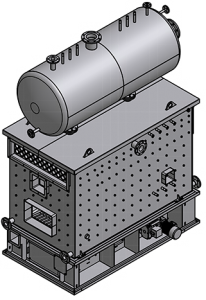

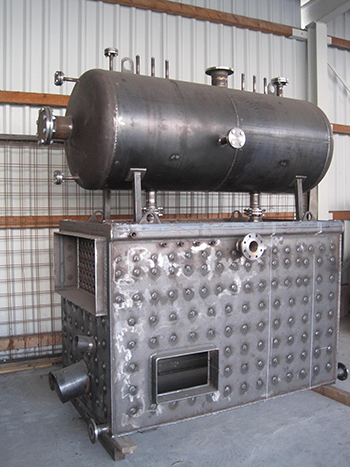

BINDER operates 3 test boilers at the head office.

With these units BINDER is able to perform test firings for non-standard fuels to ensure combustion will be within legal emission limits.

The expertise gained during the tests are the foundation of the subsequent electrical and mechanical design process, for BINDER to ensure optimised combustion of the fuel available.

Test Centerspapst2015-12-18T09:52:27+01:00